Injection Molding / Extrusion

Injection molding is one of the most important manufacturing processes for producing plastic components and is characterized by high efficiency and precision. In this process, polymeric powder is melted in an injection molding machine, injected under pressure into a mold, and then cooled to achieve the desired geometry. This method is ideally suited for mass production, as it allows for short cycle times and ensures high repeatability. Injection molding is especially relevant for industries where complex components with precise dimensional tolerances are required. Additionally, the process allows for the integration of additional functions, such as by inserting metal inserts, or the production of multi-component parts.

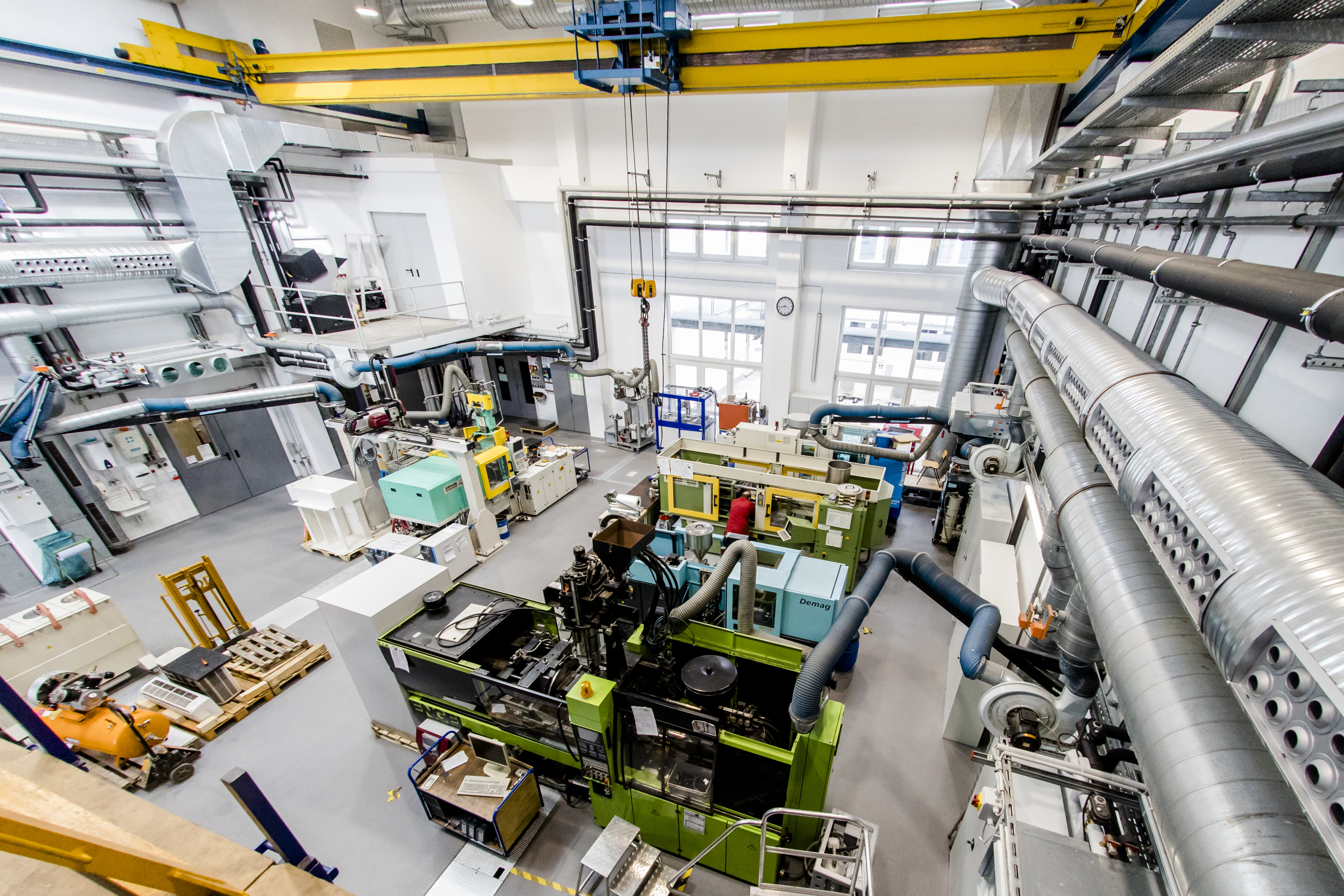

The LKT’s processing technology center is equipped with various powder mixers, twin-screw extruders, and granulators for material preparation. In the field of extrusion technology, single- and twin-screw extruders with different characteristics are used. Additionally, the LKT operates several injection molding machines.

- Laboratory mixer and granulator(Fa. Somakon Verfahrenstechnik UG | Typ: MP-T)

- Powder mixer (Fa. Mixaco Maschinenbau | Typ: LAB CM12SM)

- Twin-screw extruder (Fa. Leistritz Extrusionstechnik GmbH | Ø 18 mm | Thermoplast)

- Twin-screw extruder(Fa. Leistritz Extrusionstechnik GmbH | Ø 27 mm | Thermoplast)

- Twin-screw extruder(Fa. KraussMaffei Group | Ø 25 mm | Thermoset)

- Shear roll extruder (Fa. Bellaform GmbH | Typ: BSW100 | Ø 100 mm |Thermoplast, Thermoset)

- Granulator (Fa. Rapid Group GmbH | Typ: 1521)

- Granulator (Fa. Rapid Group GmbH | Typ: G150 21)

- Granulator (Fa. Rapid Group GmbH | Typ: G200 36)

- Intermittent hot press (Fa. Teubert Maschinenbau GmbH | Typ: HP007, 25 Zoll)

- Intermittent hot press (Fa. Teubert Maschinenbau GmbH | Typ: HP019, 50 Zoll)

- Multilayer foil machine (Fa. Dr. Collin GmbH | Typ: Special construction)

- Single-screw extruder (Fa. Extrudex GmbH | Ø 20 mm)

- Single-screw extruder (Fa. Dr. Collin GmbH | Ø 30 mm)

- Twin-screw extruder (Fa. Fill GmbH | Ø 25 mm)

- Twin-screw extruder (Fa. Fill GmbH | Ø 25 mm)

- 1-component injection molding machine (Fa. Christmann Kunststofftechnik | Ø 14 mm |Thermoplast)

- 1-component injection molding machine (Fa. Sumitomo (SHI) Demag Plastics Machinery GmbH | Ø 18 mm | Thermoplast)

- 1-component injection molding machine (Fa. KraussMaffei Group | Ø 30 mm | Thermoset)

- 1-component injection molding machine (Fa. Arburg GmbH + Co KG | Ø [25 | 40] mm |Thermoplast)

- 2-component injection molding machine (Fa. Arburg GmbH + Co KG | Ø [15 | 18] mm |Thermoplast)

- 2-component injection molding machine (Fa. Engel Deutschland GmbH | Ø [25 | 30] mm |Thermoplast)