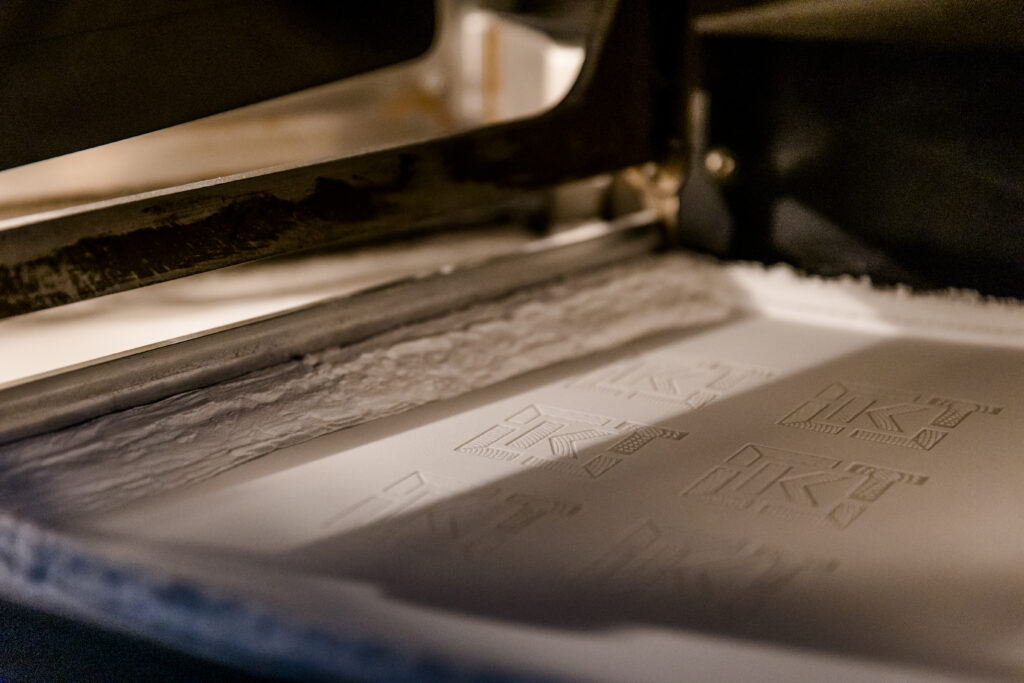

In powder bed-based additive manufacturing processes, which include the selective laser beam melting (SLS) of polymers, a powdery starting material is selectively melted by applying energy from a laser beam. The prerequisite for processing in SLS is that the starting material is available as a fine powder with bulk material properties that are as defined as possible (e.g. particle size, shape and bulk density). To date, the range of commercially available materials has been limited to a few semi-crystalline thermoplastics such as polyamide 12 (PA 12) and polyether ether ketone (PEEK).

Properties such as thermal conductivity as well as mechanical properties can be increased through targeted modification of the base material by adding fillers and additives. Due to the inherent avoidance of support structures, powder bed-based processes offer a wide range of geometric degrees of freedom and a high degree of functional integration.

Research activities at the LKT are dedicated to overcoming these material restrictions with the aim of creating new fields of application for additively manufactured components. In the field of SLS, research focuses on the analysis, preparation and processing of new plastic powders with technical relevance. Another focus is on polymer-based multiphase systems such as filled systems and polymer blends for the production of functionalized components.

In its industrially established form, SLS is based on what is known as quasi-isothermal process control, in which the build chamber and the powdered material it contains are heated to temperatures just below the crystallization melting point. The process window therefore lies between the crystallization and melting temperatures in order to prevent premature crystallization of the material. The enthalpy required to melt the powder particles is introduced via laser exposure. The disadvantages of this process are the long non-productive times, the need for continuous temperature control and the ageing and associated limited recyclability of the powder material. In contrast, the variothermal process control developed at the LKT does not require a build chamber heating, so that the energy input is provided exclusively by the laser beam. Based on scale-invariant, fractal exposure strategies and the mesoscopic discretization of material shrinkage, it is possible to process semi-crystalline plastics both at temperatures below the crystallization temperature and below the glass transition temperature. This process allows the processing of thermomechanically complex, functionalized and highly filled materials as well as temperature-sensitive materials due to the time-limited temperature effect. LKT’s research focuses on the investigation of time, process and geometry relationships as well as the development and qualification of novel material systems.

The integration of flame retardant functionalities in SLS is crucial to reduce the fire risk of additively manufactured plastic parts in a wide range of applications. SLS is used in various industries such as aerospace, automotive and electronics where materials need to be heat and fire resistant. Flame retardants are added to the powder to minimize the flammability of the components. In this context, we at LKT develop highly efficient, innovative flame retardant solutions with a decisive focus on the recyclability of SLS powders. In addition to the standard UL-94 and LOI tests, our fire testing also includes a cone calorimeter test, in which the gas phase products can be analyzed using an FTIR unit or GC-MS and evaluated in terms of their toxicity.

Polymers offer a high potential for adaptation of chemical, physical and mechanical properties and therefore a high potential for use in medical engineering. SLS is becoming increasingly widespread in medical technology, as this process can be used to realize patient- and application-specific solutions, e.g. for synthetic soft tissue replacement or system technology. The focus here is on the processing of temperature-sensitive material systems using variothermal process strategies, for example systems modified by hydrogel formers. Furthermore, individualized implants for corrective osteotomy can be produced. Another focus is on the development of flame-retardant components for use in diagnostic and large-scale devices that are subject to strict regulations for medical use.

Process fluctuations during SLS can lead to intolerable quality defects in the component. The layer-by-layer construction process results in different accuracies and component properties in the three spatial directions, such as mechanical properties or fluctuations in component density. In order to reduce the error rate as much as possible, important process variables and steps that influence quality must be identified and, based on this, a process-controlling quality inspection must be embedded directly into the manufacturing process. As part of this, the LKT is working on strategies for integrating dimensional inspection technology into the additive manufacturing process as well as the correlation between process parameters and component shape in order to be able to correct manufacturing deficits inline. The aim is to provide qualified measurement and inspection technologies as well as strategies for incremental in-line inspection in additive manufacturing. Process monitoring, which is ultimately adapted to the respective manufacturing process and enables the active correction of quality defects, creates the basis for optimal dynamic and fully automated process control. Further research work also addresses the deep learning-based real-time development of new materials and the batch-specific, process-integrated and automated adaptation of exposure parameterization, enabling the combination of previously conflicting component properties.

Collaborative Research Centre 814

- Additive Manufacturing

- Homepage: SFB 814

- ended in December 2025

- Research at LKT in the transfer phase: Flame retardant additive plastic components (T06), Polypropylene components with improved mechanical properties through adjustment of the morphologies (T10)

- Contact person at LKT: Samuel Schlicht, M.Sc., M.Sc.

- Book publication: “Progress in Powder Based Additive Manufacturing“, open access

Samuel Schlicht, M.Sc., M.Sc.

Institute of Polymer Technology

Additive Manufacturing

- Phone number: +49 9131 85-71073

- Email: samuel.schlicht@fau.de