Polymer Bonded Magnets

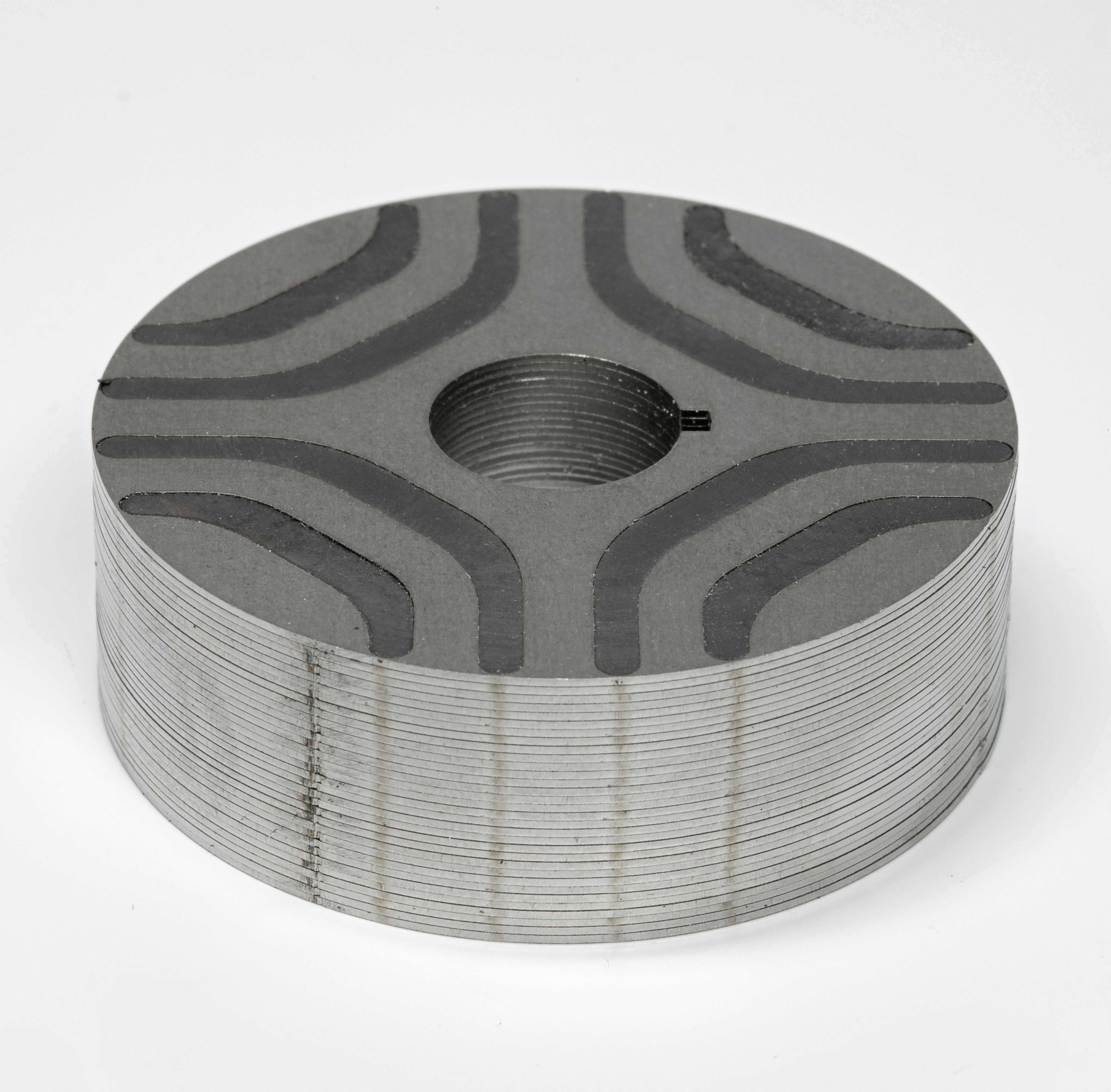

Polymer bonded magnets are composite materials consisting of a polymer matrix, hard magnetic filler particles and different additives. In comparison to conventionally produced sintered magnets, plastic bonded permanent magnets have a greater freedom of design regarding shape and magnetizing structure. Thus, they enable the use in new areas of application, such as sensors and drive technology. The injection moulding process allows the efficient production of dimensionally accurate permanent magnets with complex magnetizing structures, which can be individually adapted to the respective application. In order to utilize the full material potential, the filler particles have to be oriented in the injection mould within the plastic melt during the process. The resulting filler orientation and, thus, the magnetic properties of the part strongly depend on various factors, such as the magnetic field in the cavity, material-specific properties of the compound, as well as processing properties.

The focus of the research activities at the LKT are determining the effects of a compound’s composition, such as the type of filler particles, the filling degree of the filler particles and additives, the tool design, such as the integration of the magnetic field inside the cavity, and the processing parameters used with regard to the magnetic and mechanical properties and the processability of the compounds. The aim of the research is the achievement of high peak flux densities, as well as the precise generation of defined magnetizing structures. Fur-thermore, the LKT deals with the design of the magnetic field inside the injection moulding tool by using magnetostatic simulations.

Dr.-Ing. Uta Rösel

Institute of Polymer Technology

Processing (Head of Department)

- Phone number: +49913185-71002

- Email: uta.ur.roesel@fau.de